Hexcel

How Hexcel’s team of planners saved hundreds of hours thanks to frePPLe advanced production planning features

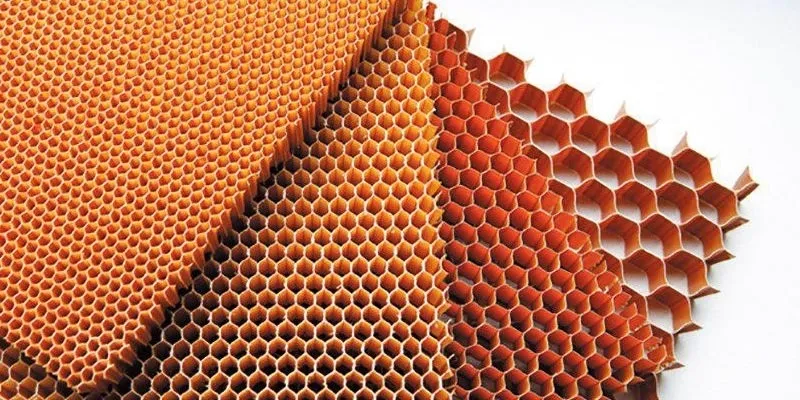

Hexcel is a global leader in manufacturing advanced composite materials for the commercial aerospace, space & defense, and industrial markets. That includes everything from carbon fibers and reinforcement fabrics to prepregs, honeycomb core, tooling materials and more.

With more than 6500 employees and a turnover exceeding $2 billion, Hexcel has 23 manufacturing sites in addition to its research & technology, sales and corporate offices globally.

The Challenge

“Before using frePPLe, we were used to planning our production with Excel spreadsheets” says Hexcel’s Supply Chain Manager. “The whole process is error-prone and requires an awful lot of time.” Moreover, the team had to manually import and export data out of the internal system. Data integration was a clear problem.

As they wanted to shift towards a faster, more agile solution, the main challenge consisted in getting the buy-in from the management. “Implementing an APS solution like frePPLe in a company our size takes time, effort, and support from the top. It comes with a lot of convincing, testing, and learning. But I’m very glad we did,” comments the Supply Chain Manager. “What used to take 20 hours to plan can now be managed in frePPLe within minutes!”

The Solution

He goes on: “With frePPLe, we are now able to issue a much more realistic forecast thanks to their advanced constraints planning features. The software is web- based, very good, and easy to use. I’ve particularly appreciated the availability of the frePPLe team. At the beginning I had a lot of questions and they responded very quickly.”

The planning team now has a clear view of the production plan and forecast for the next 18 months. Each month, they review and input new data in a very short amount of time, then refresh the plan. That’s all it takes compared to the painful and time-consuming process they had in place in the past.