Dutch Manufacturer Is Driving Efficiency With Total Zebra Technologies Warehouse Solution

Wavin, founded in 1955, is a B2B Dutch manufacturer of plastic pipes, predominantly for drainage and water supply purposes. Wavin delivers innovative solutions for construction and infrastructure worldwide, providing plastic pipe systems and products for tap water, surface heating and cooling, soil and waste, rain water, distribution of drinking water, and gas and telecom applications; its aim is to deliver safe and efficient water supplies, better sanitation and hygiene, climate-proof cities and better construction performance. Wavin is part of Orbia, a community of companies with a common goal: “To advance life around the world.” Wavin has over 11,500 employees in more than 40 countries.

Challenge

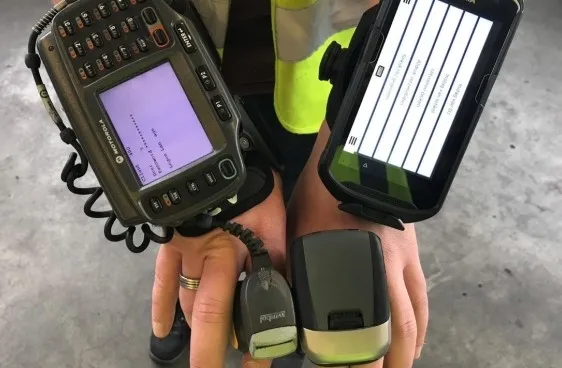

Wavin uses a wide range of Zebra Technologies hardware at its sites across Europe and knows and trusts the Zebra brand. For this specific project, Wavin was looking to update its outdated scanners, including Zebra’s MC9090, which it had deployed over ten years ago, at its Hardenberg site in the Netherlands. These devices were coming to end-of-life, the screens were small, with the Wavelink Telnet emulation text being hard to read for the older demographic of workers, and there were issues with broken cables on the previous ring scanners.

Wavin started its search for the latest wireless and RF scanning technology at the Logistica Exhibition in Utrecht. It was looking to deploy high-performance 2D scanners, with large touch screens and the option of a familiar keyboard, as well as Bluetooth ring scanners. Having assessed the market and tested devices, including tablets, from various suppliers, the Wavin teams immediately preferred the Zebra ruggedised devices; these were delivered by Wavin’s partner of over 13 years and long-term Zebra Gold Partner, Actemium. Actemium provides turnkey solutions to companies worldwide, delivering a range of safe and sustainable systems and services across the entire industrial life cycle.

Solution

Following the Zebra TC52 Touch Computers and RS507 Cordless Ring Imagers deployment, Wavin has now equipped its teams with Zebra MC9300 Ultra-Rugged Mobile Touch Computers and Zebra VC8300 Vehicle Mount Computers, to complement its extensive Zebra range.

Actemium preconfigured some of the MC9300s and VC8300s with SOTI® MobiControl before providing a manual for Wavin to configure the devices itself, at Wavin’s request. Actemium has also created a bespoke security profile for Wavin in SOTI MobiControl, so its employees can only open work apps on screen. Wavin, meanwhile, uses SOTI MobiControl to centrally manage and update the Zebra devices. Regular updates were particularly important while Wavin perfected the Wavelink Telnet to Wavelink Ivanti Velocity upgrade, possible due to the Android migration; this involved moving from plain green screen text, which only filled approximately 60% of the screen, to a full-screen, digital, intuitive interface with a touch screen and flexible font sizes. Wavin also uses the quick and simple method of Zebra StageNow to configure SOTI MobiControl, wireless settings or pick list modes, for example, and Zebra’s LifeGuard™ for Android™ for ongoing OS security updates and support.

Warehouse teams use the Zebra devices in interior and exterior warehouse zones, with the devices connecting over WLAN. The Velocity applications connect to approximately 100 job-specific screens in Wavin’s SAP warehouse management system. Teams use the Zebra TC52s with arm mounts and Bluetooth ring scanners (to eliminate cable breaks) for hands-free picking of smaller items in the shop area. These items are picked into boxes in shopping carts and transferred on mixed pallets to the staging area, where operators use the Zebra MC9300 to sort and transfer boxes to the correct pallet for each customer. Forklift drivers use the VC8300s to manage picking from the 15 rows of high-stacked bulk pallets and when lifting pallets onto the trucks for dispatch.

Results

Deploying the latest Android Zebra technology has delivered numerous benefits for Wavin. Teams can work more efficiently as the devices are completely ruggedized, have excellent battery life and maintain strong Wi-Fi connectivity across Wavin’s extensive plant, including in far-reaching exterior locations. The optimal processing speeds and advanced scanning technology, with extended scan range, means teams can pick more orders, faster. The Zebra devices have also been designed with the user in mind, weighted appropriately for long shifts in the hand and with a front-facing camera so operators can scan barcodes from multiple angles. Moreover, operators wanted to keep the option of physical keyboards, as well as having bigger screens; with the move to Android and Velocity, it is easier for operators to read the text, which now fills the whole screen with user-friendly, intuitive applications. Wavin’s IT teams, meanwhile, benefit from the time savings, maximum uptime and ease of central configuration, management and securing of devices.

Moving forward, Wavin will look to the future to keep its Hardenberg warehouse working at optimal performance; it will continue to innovate and work with Zebra Technologies and Actemium to deploy the latest technology, such as the new Zebra rugged HD4000 Enterprise Head-Mounted Displays and smart cabinets. Due to the success of this project, other European Wavin sites are now looking at installing further Zebra Android technology.

“The Zebra devices are perfectly suited to our challenging warehouse environment. Users love the new computers and were convinced after just 30 minutes of testing! The scan engine, processing speeds and connectivity are all very high performance and the Velocity emulator means we have an intuitive, full-screen touch-screen interface, to complement the keyboard. We have a reliable, user-friendly, future-proof solution.” Wesley Dogger, IT Analyst, Wavin Netherland

Find more details about this case